Engineering

Execution

Installation

Services

Solutions

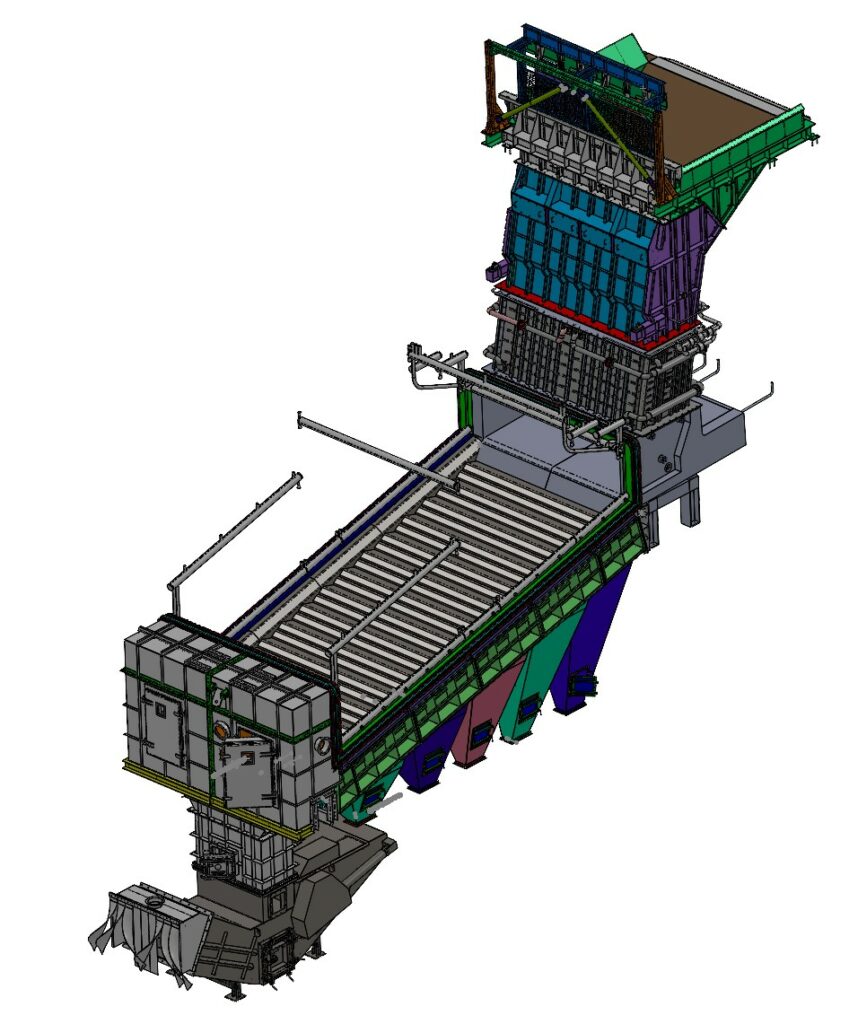

swisscomb - Grate Combustion

Jahrzehntelanges Expertenwissen umgesetzt in ein einzigartiger Rostfeuerungssystem

Modular, individually adaptable and exceptionally durable. These key features of our technology speak for themselves. The swisscomb grate combustion system masters all requirements with excellence, whether for household and commercial waste, substitute fuel or biomass. The factors characterising our technology are highest energy yield, minimum residues and low pollution emission - tested, used and proven.

The main feature of the swisscomb grate combustion are the individually driven and water cooled grate steps. They are made of special composite material and very resistent to wear and tear - the result is a long service life with a low replacement rate.

The specially developed swisscomb Combustion-Control-System monitors and adjusts permanently the grate step movement and controls the supply of combustion air. The system guarantees a constant release of energy with minimal emissions - even with a change in fuel composition.

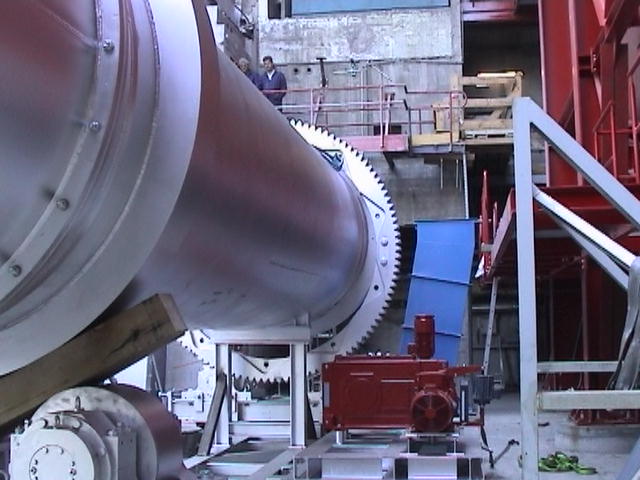

swisscomb - Hazardous waste installations

A sustainable and eco-friendly solution for hazardous waste

Are you looking for a safe and environmental friendly solution for your hazardous waste? You are right with us! We are experts for the incineration of solid, pasty, liquid and gaseous hazardous waste in our modern hazardous waste incineration.

In the incineration technology developed by swisscomb , hazardous waste such as chemicals, oils or medicines are treated thermally. The pollutants in the waste are destroyed and the resulting heat from the combustion can be used to generate electricity and provide district heating for industrial and commercial areas.

swisscomb hazardous waste incinerators make a direct contribution to environmental protection and resource conservation, as they prevent hazardous substances from getting into the air, water or soil.

Benefits for the environment and society:

- Reducing the waste volume and avoiding dumping hazardous substances that can contaminate groundwater or soil.

- Producing clean energy from a waste material that would have no use otherwise. Therefore contributing to reduce CO2 emissions and conserve fossil resources.

- Disposing of waste safely and in a controlled manner by complying with strict legal regulations on emissions and using modern exhaust gas cleaning technologies

- Creating jobs and adding value to the region in which the installation is operating

swisscomb - Engineering

Solutions that are individually tailored to the customers and their system

Many existing installations have been in use for decades - to keep operating with state-of-art technology and meet the changing legal regulations, swisscomb offers renewal solutions so that such installations can continue to operate.

Combined with individually coordinated measures for the customer's investment, keeps the cost far below a newly built installation.

Even for plants in operation, very often only a few interventions and adaptions to existing systems are required to significantly increase performance and reliability. We are convinced the engineers from swisscomb find the right solution, with conventional grate combustion system or with hazardous waste incinerators.

swisscomb - Production and Service

Our project engineers and installation specialists ensure that everything is installed and commissioned correctly

Thanks to our in-house production, we are able to supply our customers with wear and spare parts in original quality. In addition, we can analyse components from third-party systems in our engineering department and offer the customer optimised solutions as a concept as well as produce them - a complete package with advantages.